Superconductivity

a history

Superconductors transport electrical energy without any electrical resistance and thus without losses. In addition, superconductors are able to carry more energy than conventional copper or aluminum conductors of the same cross-section.

The discovery of superconductors dates back over 100 years. The effect of superconductivity was first discovered in 1911 by Heike Kamerlingh Onnes during experiments with liquid helium. In 1913, he was awarded the Nobel Prize in Physics. In 1986 Johannes Georg Bednorz and Karl Alexander Müller discovered high-temperature superconductors during their research at IBM Zürich Research Laboratory. These materials become superconducting at higher temperatures. For their work, they were awarded the Nobel Prize in Physics in 1987.

Vision Electric Super Conductors continues in their footsteps by developing this great technology into innovative industrial solutions. Be a part of this history - let us talk about your applications.

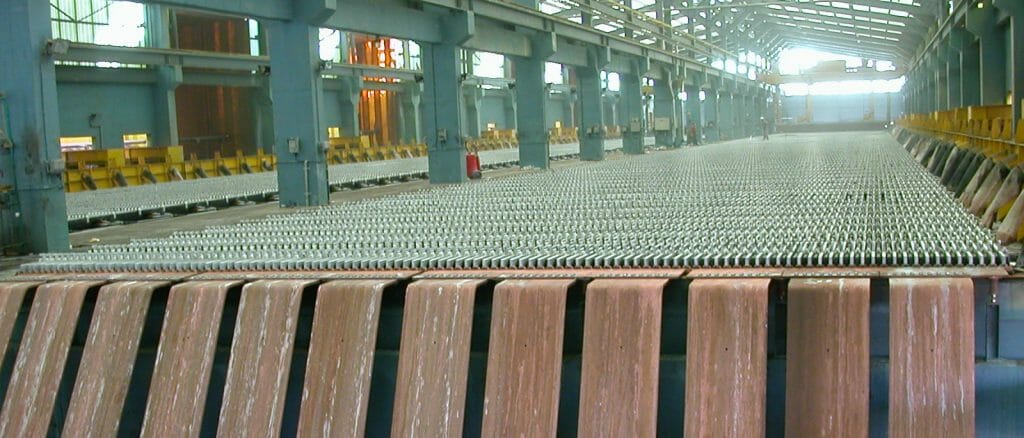

Industrial Applications

reduce CO2 emissions

With ICE®Bar, we offer a turnkey system that enables you to transmit currents starting from 10 kA without losses over any distance. This solution is particularly suited for power-intensive industries. The ICE®Bar system includes superconducting rails, cryogenic technology, conventional copper and aluminum connections, as well as comprehensive measurement and control technology for monitoring and management. You receive the complete solution from a single source.

In addition to loss-free power transmission, the system requires significantly less space. It is IP 68 certified, meaning it is sealed against water and dust, and meets the highest safety standards. Furthermore, it requires only a fraction of the materials used in conventional systems, reducing logistical effort and associated costs.

With ICE®Bar, we offer a turnkey system that enables you to transmit currents starting from 10 kA without losses over any distance. This solution is particularly suited for power-intensive industries. The ICE®Bar system includes superconducting rails, cryogenic technology, conventional copper and aluminum connections, as well as comprehensive measurement and control technology for monitoring and management. You receive the complete solution from a single source.

In addition to loss-free power transmission, the system requires significantly less space. It is IP 68 certified, meaning it is sealed against water and dust, and meets the highest safety standards. Furthermore, it requires only a fraction of the materials used in conventional systems, reducing logistical effort and associated costs.

Data Centers

new efficient design

ICE®Bar and ICE®Link enable you to rethink data center design and develop and implement new, more efficient concepts. This turnkey system generates no waste heat, poses no fire hazard, and does not require electromagnetic shielding from IT hardware. With our technology, you can transmit high currents loss-free, optimize space utilization, and enhance the efficiency of your data center.

Compared to conventional busbar systems, ICE®Bar is significantly more compact and allows for tight bending radii. As a result, this system enables you to utilize available space more effectively, gaining a clear cost advantage.

Fusion Power

the solution for fusion

The construction of electromagnets for plasma confinement poses unique challenges. The high currents, magnetic fields, and forces involved require specialized conductor materials. Simplify your work by choosing conductors specifically designed for these demanding conditions.

The Cross Conductor (CroCo) is a high-temperature superconductor (HTS) developed by the Karlsruhe Institute of Technology and exclusively licensed and manufactured by Vision Electric Super Conductors.

Power Grids

for a sustainable future

The modernization of power distribution networks presents operators with challenging tasks. In addition to expansion at the high- and medium-voltage levels, the capacity of distribution networks in urban areas must be adapted to meet the continuously increasing electrical loads.

Furthermore, superconducting technology enables the integration of all energy generation and storage facilities into a highly efficient energy park network, operated with direct current at the low-voltage level. This eliminates the need for costly power converters at each individual facility.

Components

connecting systems

We manufacture and supply various components for connecting and operating superconducting systems in combination with conventional systems. Of course, we also develop custom components tailored to your specific projects.

We hold the exclusive production and distribution rights for the Cross Conductor, developed by the Karlsruhe Institute of Technology. This unique superconductor is flexible and can be wound onto a reel, making it particularly suitable for installation in pipes.

Engineering Services

our know-how, your success

We deliver the following services for all high current, high power and superconductor systems:

- Basic engineering and feasibility studies

- Design engineering and layout

- Detail engineering and mathematical models

- Thermodynamic and temperature models

- Cross section optimization and thermal load calculation

- Definiton of materials and equipment

- Stress analysis and force calculation

- Installation and operation manuals creation

- Risk analysis, assessment and remedy measures

- Quality inspection

- Tender specifications

- Maintenance and operation supervision